Meler Story

Meler Hot Melt

Gluing Systems

Meler has been developing and building hot melt gluing systems for over 30 years and is the world leader in hot melt gluing technology. With reliable performance, a comprehensive range of hot glue melting equipment to suit every application, built-in best in class energy efficiency and every machine is supported and serviced by Automaint Solutions.

Why Choose Meler &

Automaint Solutions?

- Automaint Solutions are the official Australian & New Zealand agents for Meler Hot Melt Gluing Systems

- We carry an extensive range of spare parts for Meler systems; heated hoses, guns, modules, nozzles, solenoid valves and more

- Genuine 24/7 support and service with trained technicians ready to assist you anytime

- Fully equipped service centre able to get your equipment running quickly in the event of a breakdown

New Meler Micron+ Series

The Hot Melt Glue System Designed for Industry 4.0

Class-Leading Energy Efficiency for Hot Glue Melting Systems

Remote Communication, Control and Access to Real-Time Data

Leading Digitisation and Interconnectivity to Support Industry 4.0

Full System Remote Control & Industry-Leading Safety for Operators

Meler Hot Melt Glue Product Range

B4 Series

Melter

The most cost effective, reliable and robust hot glue melters for manual and small consumption automatic applications.

With a 4 kg tank capacity, up to 2 hose connections, either piston or gear pump options available. The B4 will melt adhesive at a maximum rate of 6 kg per hour.

Micron Series Melter

New cutting edge design and technology has been combined to produce the new Micron range of systems. This impressive tank is up to 60% more energy efficient than its rivals, in addition to improved pump and melt rates. The Micron is also operator and maintenance friendly with options of 5, 10, 20 and 35 litre tanks and up to 6 hose connections across each tank size.

Meler PUR & POR Melters

B4 PUR, B4 Non Stop, Micron PUR – LC and the Non-Stop. This range of PUR hot glue melters when using PUR hot melt adhesive from 2kg blocks to 5kg and 20kg pails. Precise gear pumps and a dry air system prevent curing. With the adhesive being melted in a tank or, in the case of the non stop systems, a reservoir, production does not have to stop to refill.

Melt-on-Demand Series Melters

The new Meler Micron MOD hot glue melters are specially designed to preserve the adhesive in low-medium consumption applications. The main feature of this machine is the “Melt on Demand” system that melts the adhesive only when it is needed, thus eliminating charring problems whilst also significantly reducing power consumption.

Genuine 24/7 Service & Support

Automaint Solutions are the Australian & New Zealand official partners for Meler Hot Melt Gluing Systems. Our experienced and highly trained hot melt glue service technicians are only a phone call away, day or night, should you require advice, essential spare parts or a technicians on-site assistance with your hot melt glue equipment.

Hot Melt Glue Applications

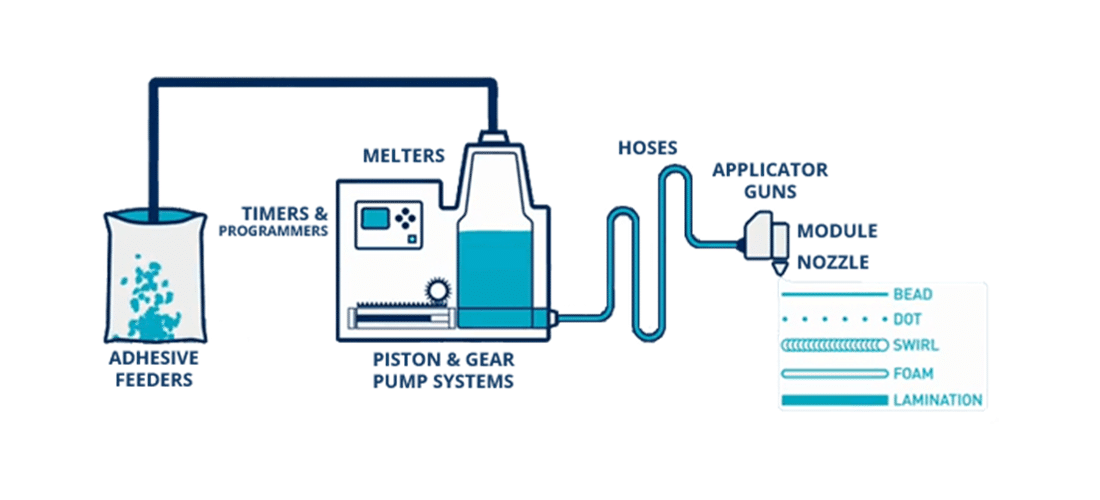

This video provides an overview of the full system functionality of a Meler hot melt gluing system and highlights the parts of each Meler system, that make up the hot melt gluing system which delivers a wide range of hot melt glues to various products.

If you would like to learn more about how a hot melt gluing system would benefit your business, one of our gluing systems experts will gladly explain the process in detail and discuss your hot melt gluing requirements.

Focke Meler

Focke Meler Gluing Solutions is a group of companies with more than 30 years of experience in developing and manufacturing systems for applying adhesives and sealants.

The main goal of Focke Meler is to become your best supplier, wherever you are and whatever your need. With a driven focus on continual research & development to ensure their machines are world leaders in technology, features, ease of use and low energy consumption.

Automaint Solutions

Automaint Solutions is the authorised distributor of genuine Meler equipment, parts and service for Australia & New Zealand.

With over 23 years of experience servicing the manufacturing industry the Automaint Solutions team have significant experience within the packaging, pharmaceutical, food & beverage and automotive industries. We offer our customers a full automation consulting and project management service covering everything from control system design to maintenance support and training.

5th August 2020

COVID-19 Statement

At Automaint Solutions we pride ourselves on delivering critical and responsive breakdown and service support to all our customers.

In light of the current situation in Melbourne and the newly introduced Stage 4 lockdown, we want to assure you that as always, the health and safety of our customers and team members is our top priority.

Automaint Solutions supports many of the critical businesses that manufacture essential products for Australia. We will continue to support our industry with service & maintenance that is essential to keep Australian manufacturing operational.

As of Wednesday, 5th August:

- Automaint Solutions is open and both our Victorian & South Australian offices are strictly adhering to a COVID Safe Workplace plan.

- Australia Wide breakdown response will continue from our Victorian & South Australian offices for both our 24/7 customers and standard time customers..

- All servicing will continue based on customer requirements.

- Quoting of projects, machines and servicing will continue.

- Projects within the Automaint Workshop will continue. Although affected by suppliers’ changes during this time, we will endeavour to keep projects on track.

- Spare parts supply will continue.

- We are not accepting visitors to Melbourne head office or South Australia factory for non-essential meetings. However please call the office, Automaint will allocate the correct person to contact by other means (Phone, Skype, WhatsApp or Facetime) and continue the Automaint way.

We will keep you updated should any changes be implemented. If you are unsure and have questions, please do not hesitate to call us (03) 9330 2678.