B4 VS PUR AND THE B4 NON-STOP MELER B4 NON-STOP

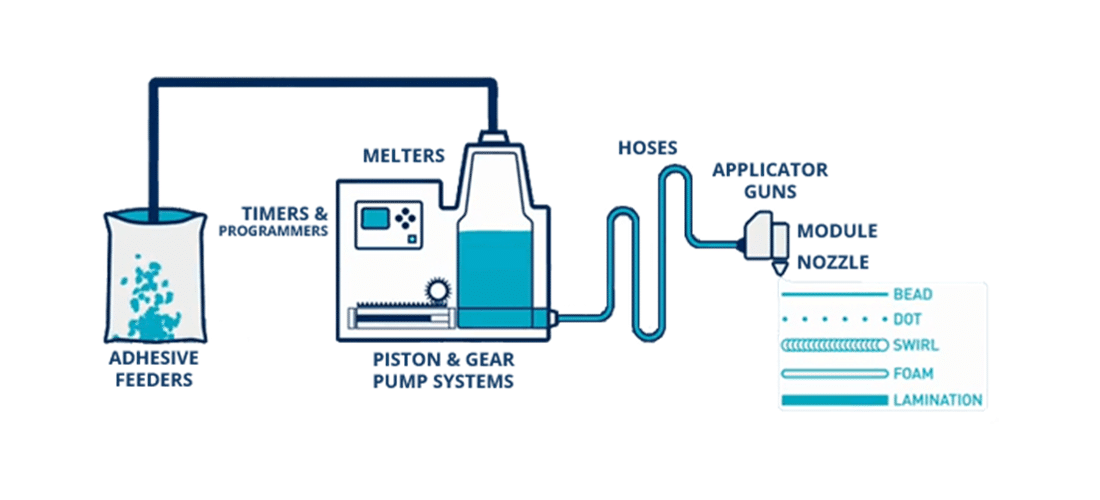

Adhesive melters work with moisture cure reactive polyurethane (PUR) hot melt adhesives in 2, 3 or 4kg foil-encased blocks or form-liner slugs with foil bottoms with maximum diameter 130 mm. The B4s user-friendly design provides secure, precise and easy operation. It also offers simple maintenance, ease of cleaning and reduced adhesive waste.

The concept of ‘melt on demand’ is to allow for inconsistent production cycles. After using some of the adhesive you can stop and start the machine after hours or days. The Meler B4 NON-STOP melts only the perfect amount of adhesive for the application, and protects the rest from melting. No extra dry air or nitrogen supply is necessary due to the air tight cylinder pressing system. The pressure and melting system allows the complete use of the adhesive, avoiding any waste of PUR adhesive.

Electronic Control Unit

The B4 NON-STOP’s electronics control the temperatures in a range from 40ºC to 200ºC and the motor/pump speed to adapt the adhesive flow rate, manually or automatically, to the application.

Main Use

Meler B4 NON-STOP is used for manual and automatic applications with low glue consumption such as Clear Box Gluing in the Graphic Arts Industry, product assembly applications in the Automotive Industry and Wood Working Applications such as Edge-Banding, etc.